Oil & Gas

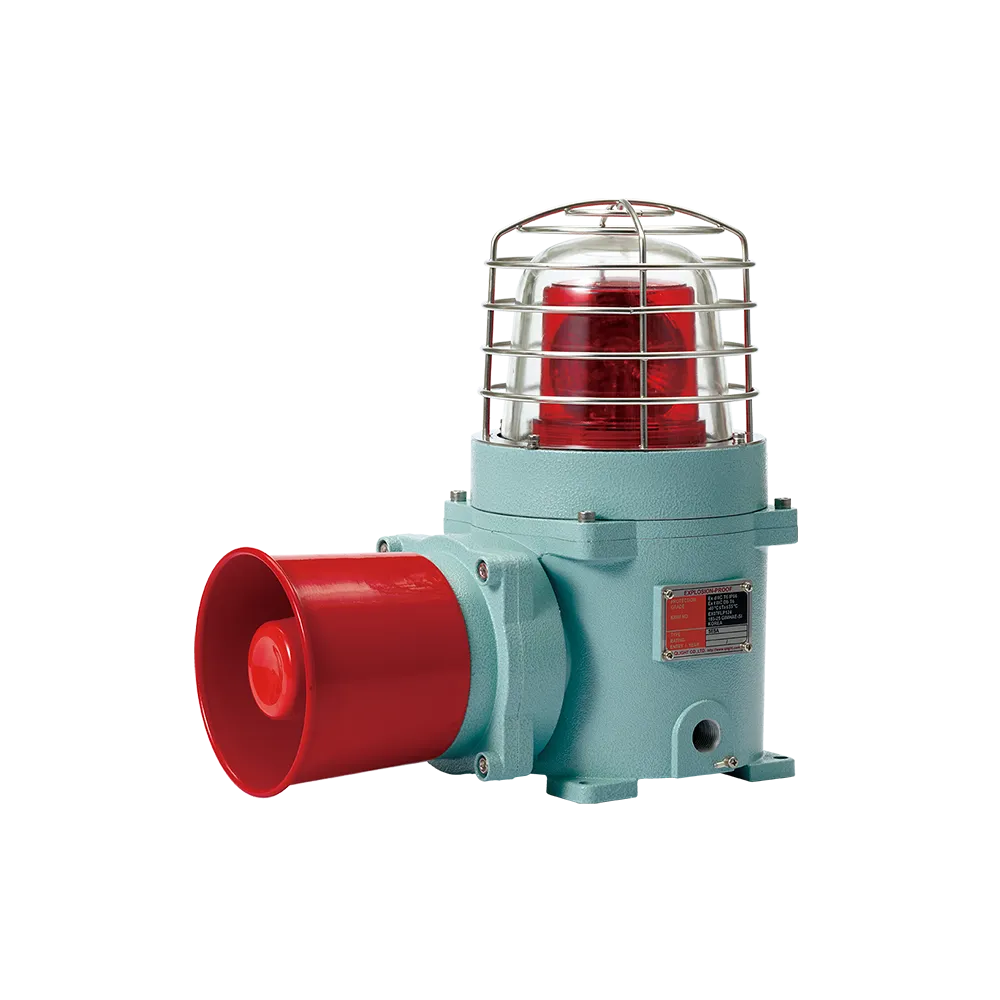

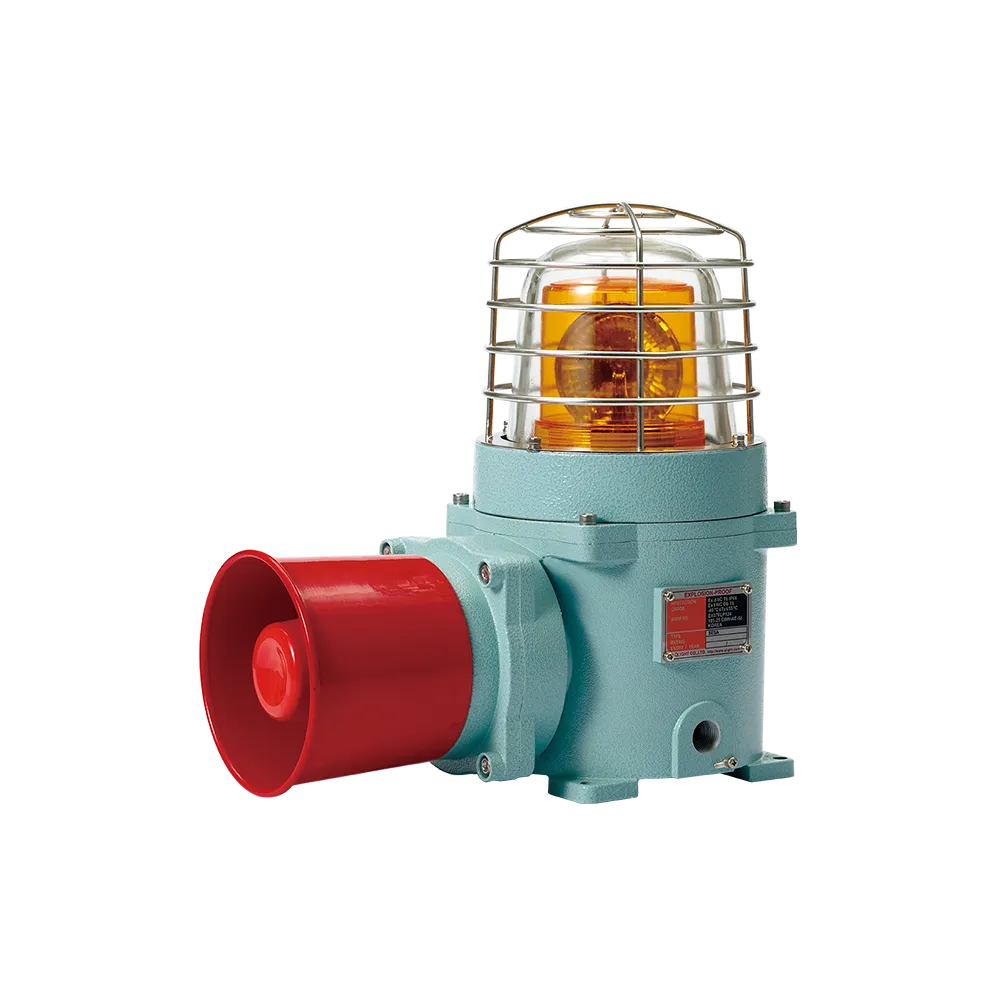

Explosion-Proof Signaling Devices for Oil and Gas

Qlight offers a comprehensive range of explosion-proof signal lighting and sounder devices, purpose-built for the demanding environments of the oil and gas industry. Engineered to meet stringent international safety standards, these solutions are ideal for use in areas where flammable gases, vapors, or dust are present. Key application areas include FPSOs (Floating Production Storage and Offloading units), offshore platforms, oil rigs, refineries, petrochemical facilities, and onshore drilling operations. Qlight's robust signaling devices provide clear, immediate alerts to ensure safe operations, enhance hazard awareness, and support compliance in high-risk zones.

Certified Explosion-Proof Design:

Ensures safe operation in hazardous environments.

High Durability:

Built to withstand harsh conditions such as high pressure, temperature, and corrosive materials.

Bright LED Lights and Loud Audible Alarms:

Provides clear visual and audible signaling.

Compliance with International Standards:

Meets IECEx, ATEX, and other safety standards.

Importance of Signal Lighting and Sounder Products in Oil and Gas

In the oil and gas industry, safeguarding personnel and critical equipment is a top priority. Signal lights and audible warning devices serve a vital function by delivering immediate, unmistakable alerts in hazardous environments. These signaling solutions are essential for accident prevention, efficient emergency coordination, and maintaining operational safety. The integration of visual and audible alerts ensures reliable communication of warnings, even in high-noise, high-risk, or visually congested environments.

Explosion Risks:

Working with flammable substances increases the risk of explosions, requiring specialized equipment to ensure safety.

Qlight’s explosion-proof products are designed to prevent ignition and ensure safe operation in hazardous areas.

Harsh Environments:

Extreme conditions such as high pressure, temperature, and corrosive materials can damage standard equipment.

Regulatory Compliance:

Meeting international safety standards and obtaining necessary certifications can be challenging.